Installation

and Maintenance

News

style advices

and curiosity

from the world

of ceramic

Guidelines for installation and maintenance

Standard UNI EN 14411 – Ceramic tiles: Definition, Classification, Characteristics and Marking, defines and provides the marking terms, requirements and criteria for high quality ceramic tiles.

Rondine S.p.A. continually tests all its tiles in accredited workshops, in accordance with the aforementioned standard. Moreover, internal quality control procedures are implemented on an ongoing basis.

Laying

Before laying at the site, the tiler should check the shade, size, and choice of material, whereas when laying the tiler should always use tiles from several boxes to obtain the ideal colour mix.

The tiler should also check the product for any obvious flaws before laying, which would not be covered by the guarantee if pointed out after laying.

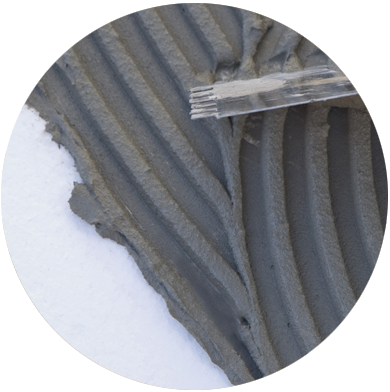

The tiler should use adhesives which are suitable for the various types of use, and follow the instructions on the packaging.

The surface to be tiled should be checked to ensure it is stable, dry and ready for tiling, and is not excessively hot or cold. The adhesive should be applied professionally such that there are no gaps between the tile and the surface. The tiler should be careful not to mark the material on the outer surface with pencils (graphite) or permanent markers, especially on products with smooth, glazed or lapped surfaces. Appropriate diamond tile cutters and special equipment should be used for the cutting and outlining operations requested by the Works Manager, especially with porcelain stoneware.

The dimension of the tile joint may vary depending on the format used, orthogonal or diagonal laying angles, and final use.

Grouting and cleaning after laying

Fillers or mortar coloured with pigments should only be used after carrying out an initial test.

For porcelain stoneware surfaces which are smooth, glazed or lapped, mortar or fillers which are contrast coloured (white tiles and anthracyte, red grouting etc.) cannot be used due to the microporosity caused by the abrasive action of the cutter during processing. With the use of cement surfacers after grouting the tiles, with the grout still fresh, any excess grout should be removed immediately with a sponge and plenty water.

A few days after laying, clean thoroughly with buffered acids to completely remove and dissolve any residue. It is also important to rinse well until the wash water runs clean. Liquid extractors are useful for removing dirty wash water, which avoids moving it from one place to another. When work has been completed the tiler should wash the floors with a water and buffered acid solution, to avoid the insufficient or late removal of grout residue leaving marks which may be difficult to remove.

Rondine recommends FILA Deterdek for this operation (follow the recommendations on the container for dilution percentages closely), which is an acid descaling agent that does not give off harmful fumes and combines the descaling action with effective cleaning. 2 For special areas of application, if waterproof grouting is required, epoxy mortar can be used.

Follow the manufacturer’s instructions on the packaging exactly and adhere to the procedures for use. When using these products, always consult expert, qualified tilers, as the incorrect application of epoxy mortars could irreversibly compromise the colour and appearance of the tiles.

The use of detergents (anti-corrosive products) which contain hydrofluoric acid could permanently damage the surface of any type of tile.

Standard maintenance

For floors with smooth surfaces we recommend cleaning daily with Fila Cleaner (adhere to the recommended dilution percentages on the container), and treat regularly with an anti-stain treatment to protect the tiles from damage caused by markers, ink, rust or other damaging products. We recommend the use of FILA products for the standard maintenance of Rondine tiles.